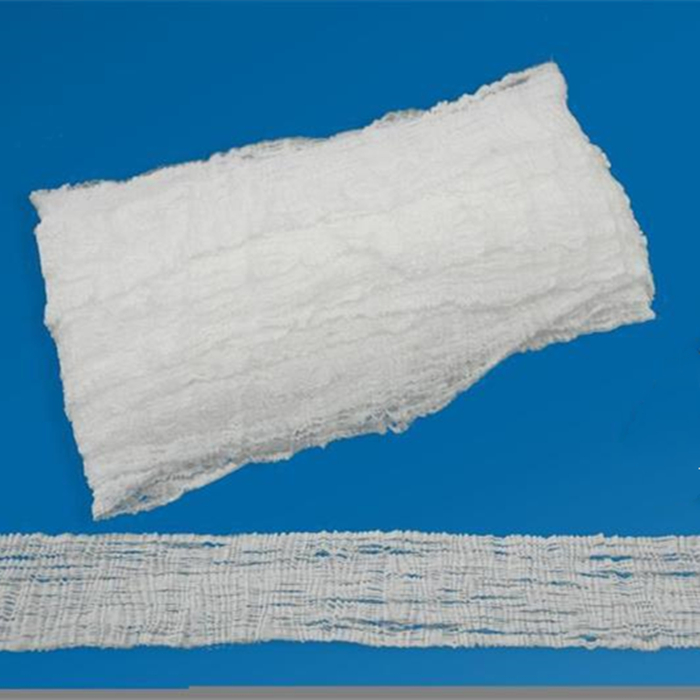

Acetate tow has become increasingly popular for use in cigarette filter rods due to its excellent filtration effects. This material is made from cellulose acetate fibers that are spun together to form a continuous filament, which is then cut into small, uniform pieces. Because of its high efficiency in removing harmful substances from cigarette smoke, acetate tow has become the go-to material for cigarette manufacturers seeking to create a safer smoking experience for their customers.

When used in cigarette filter rods, acetate tow works by trapping tar and other harmful particles as they pass through the cigarette. This results in a smoother, less harsh smoke that is better for the lungs and overall health of the smoker. In addition, the material is also effective at reducing the amount of smoke that is released into the air, making it a more environmentally friendly choice as well.

One of the key advantages of acetate tow is its uniformity and consistency. Because each piece is precisely cut to the same size and shape, cigarette manufacturers can ensure that each filter rod contains the same amount of material. This allows for greater precision in manufacturing and results in a more consistent smoking experience for the consumer.

Overall, acetate tow is a highly effective and efficient material for use in cigarette filter rods. Its ability to filter harmful substances from cigarette smoke makes it an essential component of modern cigarette manufacturing. As consumer demand for healthier smoking options continues to grow, it is likely that the use of this material will only become more widespread in the years to come.

Post time: Oct-31-2023